Breaking down silos: How data integration forms the foundation for advanced analytics

By Felipe João Pontes da Cruz, Global Solutions Leader, Actionable Insights

The evolution of data and analytics in the automotive sector

To make effective decisions in today’s disrupted automotive environment, OEMs need real time access to high quality financial and operational data. Data and analytics solutions continue to make their mark on various industries, and the automotive sector is no exception. However, what sets it apart is the apparent gradual pace of this evolution in contrast to other industries which have swiftly embraced advanced analytics. Additionally, the automotive landscape is notably complex, with numerous stakeholders influencing its operational dynamics. Achieving comprehensive data coverage requires significant time, investment, and handling to ensure business success.

Heighten the complexity of your business decision-making

Many of the challenges faced by OEMs today arise from fragmented systems and data sets that were likely never designed for advanced analytics. Traditionally, data curation across the automotive industry was for the sole purpose of producing simple, operational reporting. In order to generate meaningful metrics and KPIs, OEMs must combine data from a variety of disparate sources in multiple formats into dashboards that deliver meaningful results.

While fragmented systems and data sets pose challenges of their own, breaking down operational silos and connecting data from different domains presents huge opportunities to increase the complexity of the business decisions that can be made. This interconnected approach considers third party manufacturers, parts distributors, dealerships, and other key players to address problems in a more holistic way. By combining, for example, a retail network’s financial data with their training data, OEMs can establish whether there’s a correlation between employees with lower levels of training and retailer’s lower financial performance. This approach to data is more powerful than focusing solely on a single domain, enabling not only descriptive outcomes, but also enhancing its predictive and prescriptive capabilities.

However, to ensure the effectiveness of data and analytics solutions, it is crucial for OEMs to prioritize better practices around security, compliance, and governance. As the industry embraces interconnected data from various stakeholders, maintaining a robust framework for security and compliance becomes paramount. Implementing governance measures ensures the ethical use of data and aligns with industry standards. This not only mitigates risks associated with fragmented systems but also fosters trust among stakeholders, laying a secure foundation for the comprehensive and insightful decision-making process within the automotive landscape.

Strategic data utilization: Maximize efficiency for informed decision-making

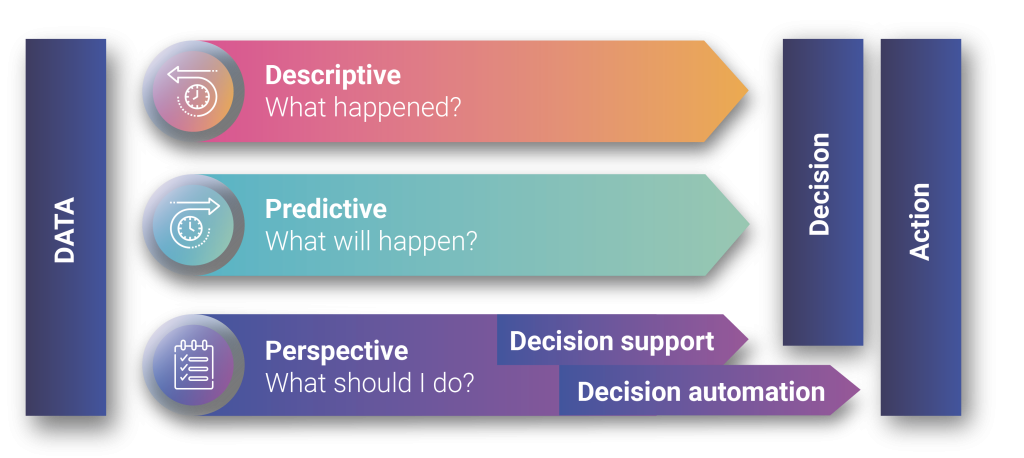

Data can be effectively employed in descriptive, predictive, and prescriptive capacities, facilitating decision support and decision automation. This approach effortlessly maximizes operational efficiency, providing a roadmap for informed and strategic decision making in various operational scenarios.

How unified data can enhance analytics

The complexity of the automotive industry means that implementation and management of new data tools and strategies is not straight forward. In contrast to industries like ecommerce, where companies typically control all aspects of their operations, the automotive ecosystem is much more fragmented. This limits access to potentially influential data, such as parts sales opportunities currently being lost to independent manufacturers. Gaining access to that data via a business partnership or data purchase would have significant benefits.

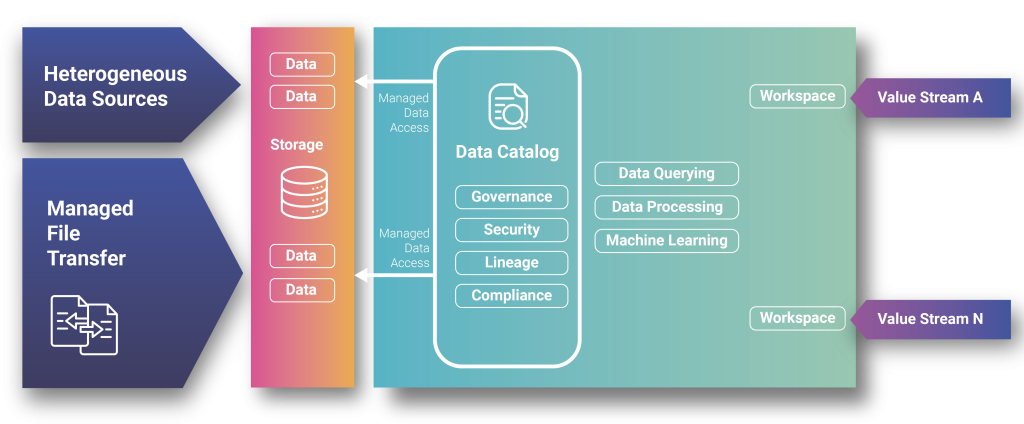

While tools such as automation and machine learning support decisions, whether they’re predictive or prescriptive, a data fabric model can help to simplify access to business data, allowing for easier consumption across the organization. Facilitated by a holistic architecture design, it catalogs various data environments in a single platform and provides a unified view, making it easily accessible and usable for various applications and users.

For companies like MSX, this technology boasts significant power, allowing us to combine data from a variety of sources and provide industry benchmarks and insight, supporting the curation of new solutions and allowing us to deliver the next generation of descriptive, predictive and prescriptive analytics tools to our customers.

The power of analytic capabilities

The first stage of achieving a higher level of data maturity is the introduction of descriptive analytics. This provides clear visibility of business processes throughout the organization and offers insight which forms the foundation of any further analysis. This profiling relies on good quality data in order to identify inefficiencies and bottle necks and introduce processes or software solutions to curate valuable outcomes.

Once OEMs have established a good level of data maturity and better understand their business, they can start to piece this together in predictive way, helping forecast future trends or challenges with a good level of accuracy, allowing them to better plan their future. This is a particularly useful tool for automotive aftersales in calculating parts demand and service capacity, for example.

Predictive analytics can also be used as the foundation for prescriptive activities. Based on these predictions, OEMs can prescribe business actions. For example, using automation and artificial intelligence, OEMs can review warranty claims and identify whether there are potential savings, either automatically processing the claim or sending it to an agent for manual investigation.

In some cases, prescriptive actions can be identified based on descriptive data using pure mathematical algorithms. For example, when deciding how to allocate a marketing budget, descriptive data can be used to calculate potential ROI, determining how much to invest into each channel.

MSX Delta Lakehouse: Our data science and analytics platform

Our Delta Lakehouse merges a multitude of data sources seamlessly, transferred directly to storage. A robust data catalog and advanced query processing mechanism efficiently organize the incoming data. Simultaneously, machine learning algorithms operate to query and process the information to generate valuable data outputs. These outputs are made accessible to consumers through unique workspaces, empowering users with actionable insights derived from the amalgamation of diverse data streams.

Optimize your business operations

These data models, tools and analysis types, when implemented in the right way, can significantly improve operational performance. Data analysis can calculate something that is close to the theoretical optimum, ensuring actions yield the best results for the business. AI can automate business decisions or facilitate decision support. While sensor data provides valuable insight into service and repair processes and helps identify inefficiencies that could result in delays or cost waste.

Today, many prescriptive actions, especially throughout the dealer network, are not necessarily determined by data, but by knowhow and expertise. But as the industry continues to evolve, OEMs and their retail networks must rely more heavily on the data available to them to identify the best practices that will deliver the best possible service to their customers and achieve overall success.

The key to successful data and analytics outcomes

Successful data and analytics models demand a robust investment in establishing a strong data foundation and efficient processes. Acquiring high-quality data tools for data generation, analysis, and cleansing is essential for achieving successful outcomes, even if predictive tasks are outsourced.

For over 30 years, MSX International has been supporting OEMs and their retail networks across the globe to review operating principles, identify new opportunities and unlock potential for growth and higher efficiency. Our Actionable Insights solutions leverage data and analytics to increase efficiency and profitability and create new revenue streams. Our Data Visualization and Diagnostic Services offer descriptive capabilities to our customers. Meanwhile, our Insight BM solution processes financial and statistical data to generate structured performance insight that supports better decision making and financial benchmarking.

For more information about how MSX Actionable Insights solutions can drive performance improvements in existing operations and identify valuable new opportunities within your business, please visit msxi.com/actionable-insights or contact Felipe Cruz at fcruz@msxi.com.